November 8, 2018 | Customer Testimonials, Job Stories, Product Knowledge

“Got Brick?”

Growth in construction activity continues to drive demand for building supplies. Six years ago Cherokee Brick and Tile needed to purchase new wheel loaders. They decided to try out 3 different wheel loaders to see which one they liked the best: the Hyundai HL955TM, a CAT 930, or a Komatsu WA270. After three years of testing and evaluation, Hyundai proved to be the best solution for Cherokee Brick’s demanding operation.

Cherokee Brick and Tile is family owned and has been in business since 1900. Mike Peavy, President, has been with the company since 1990. Cherokee Brick has two plants, one in Macon, GA and one in Jackson, Mississippi, which make about 130 million bricks a year combined.

“Hyundai cost less. We spent less money on the Hyundai and had less down time over a 3 year period than the other brands. That’s what made up my mind. Also, the operators loved them. From that point forward, we stuck with Hyundai loaders in our grinding operation, and we’ve been very happy with them.” says Mike Peavy.

Brick Making Depends Heavily on Wheel Loaders

Cherokee Brick starts the process of making a brick from the beginning with the mining of the clay. Next the clay is transported to the plant for processing through a grinding operation, which requires about four wheel loaders. Then it goes through four different mills to make the individual bricks. The whole process from grinding the clay to making a brick is about seven days.

“Brick Friendly” Wheel Loaders

The HL940 wheel loader comes with a 2.3 m3 (3.0 yd3) bucket capacity (heaped) and a standard bucket dump clearance of 2,785 mm (9.1 ft.) The HL955 TM (Tool Master) wheel loader comes with a 2.7 m3 (3.5 yd3) bucket capacity (heaped) and a standard bucket dump clearance of 2,840 mm (9.4 ft.) Add in the accurate on-board weighing system, unique bucket design for better load retention, and free use of Hyundai’s Hi MATE cellular based remote management system for five years, and you’ll find that Hyundai’s HL900 wheel loader series offers an unbeatable value.

“The Hyundai HL940 & HL955TM have proven to be dependable and reliable wheel loaders for many companies who expect high production and low cost of ownership with less downtime. The on–board weighing system with .01% +/- accuracy is just one of the many standard features Hyundai offers for maximum cycle time production, which gives Hyundai a competitive edge over the competition,” says Chad Parker, Hyundai Construction Sr. Product Specialist and Sales Trainer.

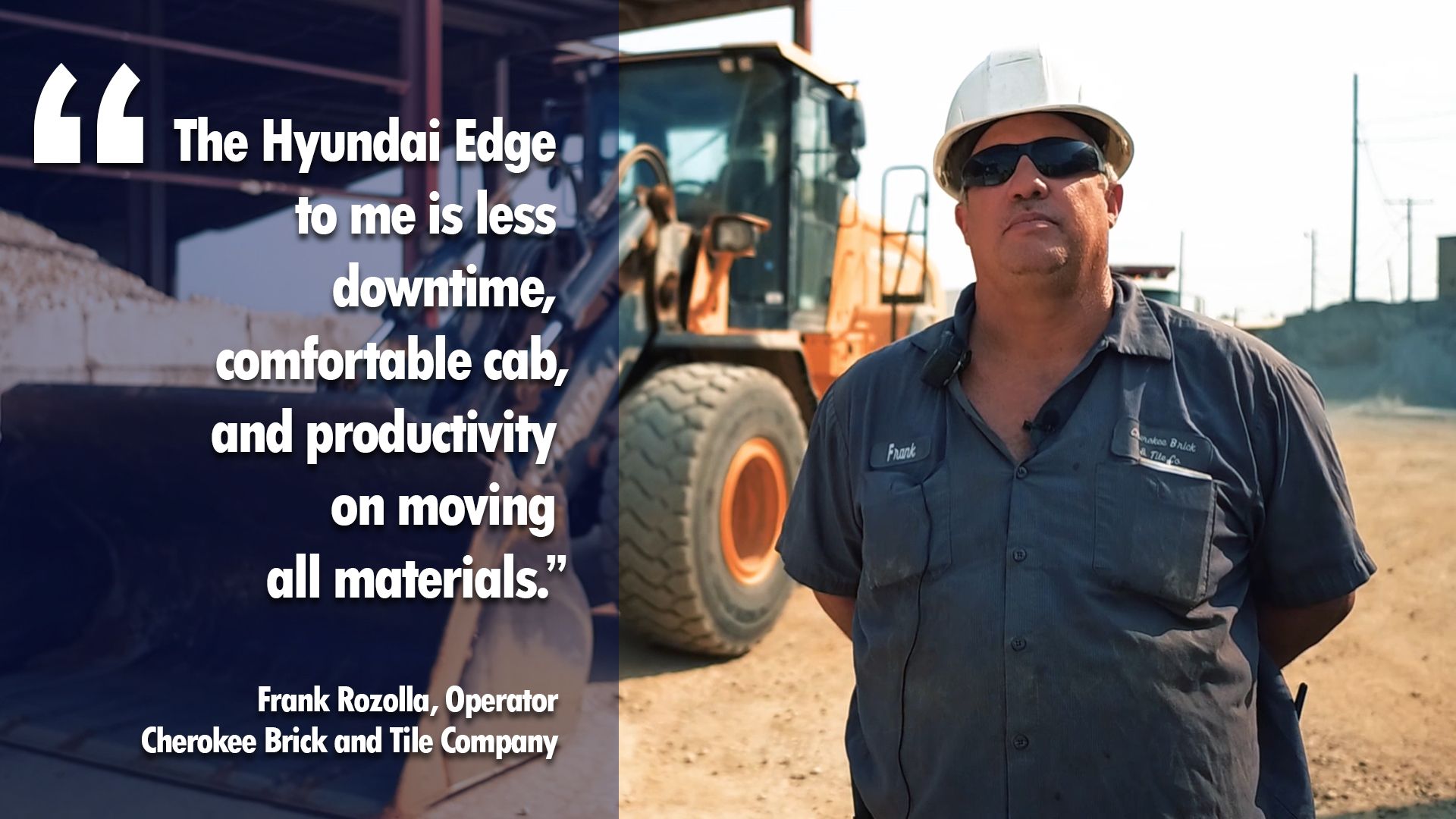

Frank Rozollo, and operator at Cherokee Brick for 10 years says the Hyundai machines are capable of doing all the necessary things they need them to do.

“The cabs ride good and the stability of the loaders are awesome. The Hyundai Edge to me is a comfortable cab for operators when they are in it 10 or 12 hours, less break down time, and we can stay productive on moving our materials,” says Frank Rozollo.

“The Hyundai Edge to me is several things. The prices are very competitive. Crosby Equipment has been very good to work with… the Hyundai loaders are very good and operator friendly. We grind about 180 tons per hour of clay and they can withstand the challenge… all day long,” says Mike Peavy.

To hear more from Mike and Frank and to see the Hyundai HL940 and HL955TM wheel loaders in action at Cherokee Brick, watch the video below.